In today’s industrial landscape, the demand for efficient, reliable, and cost-effective gas solutions has never been higher. Nitrogen gas, in particular, plays a pivotal role across a myriad of sectors, from food packaging to electronics manufacturing. This is where nitrogen gas generators come into play, offering a sustainable and convenient source of high-purity nitrogen. Gas Generation Solutions, a leader in the field, brings you this comprehensive guide to understanding nitrogen gas generators, their operation, benefits, and applications.

What Are Nitrogen Gas Generators?

Nitrogen gas generators are systems designed to produce nitrogen gas on-site, through the separation of nitrogen from other gases in the air. This technology eliminates the need for traditional delivery and storage of bottled or liquid nitrogen, providing a more efficient and cost-effective solution for industries requiring a constant supply of nitrogen gas.

How Do Nitrogen Gas Generators Work?

There are primarily two types of nitrogen gas generators: Pressure Swing Adsorption (PSA) and Membrane technology. Click here to learn more about how nitrogen generators work.

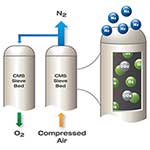

Pressure Swing Adsorption (PSA)

PSA nitrogen generators operate by passing compressed air through a vessel containing carbon molecular sieve (CMS). Under pressure, CMS adsorbs oxygen and other impurities, allowing nitrogen to pass through as a purified product gas. When the CMS becomes saturated with oxygen, the pressure is released, and the oxygen is vented to the atmosphere, regenerating the CMS for the next cycle.

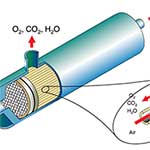

Membrane Nitrogen Generators

Membrane generators separate nitrogen from other gases using a membrane composed of bundles of hollow fibers. As compressed air passes through these fibers, oxygen, water vapor, and other gases permeate the membrane walls, leaving nitrogen as the primary product gas.

Benefits of On-Site Nitrogen Generation

Cost Efficiency

By generating nitrogen gas on-site, businesses can significantly reduce the costs associated with ordering, delivering, and storing bottled nitrogen. On-site generation provides a steady supply of nitrogen, eliminating delivery charges and rental fees for storage tanks.

Reliability

Nitrogen gas generators offer a consistent and reliable source of nitrogen, ensuring that your operations are not hindered by delays in deliveries or shortages of bottled nitrogen.

Purity Levels

On-site nitrogen generators can produce nitrogen at various purity levels, tailored to meet the specific needs of different applications. This flexibility ensures that you get the exact quality of nitrogen required for your processes.

Environmental Benefits

On-site nitrogen generation is a more sustainable option, reducing the carbon footprint associated with transporting and delivering bottled nitrogen. It also minimizes the need for heavy storage tanks and the potential for gas leaks, contributing to a safer and more environmentally friendly operation.

Applications of Nitrogen Gas Generators

Nitrogen gas generators have a wide range of applications across various industries:

- Food Packaging: Nitrogen is used to displace oxygen in food packaging, extending shelf life and preserving freshness.

- Electronics Manufacturing: High-purity nitrogen is essential in soldering processes to prevent oxidation and ensure high-quality electronic components.

- Pharmaceuticals: Nitrogen gas is used in pharmaceutical packaging to provide an inert atmosphere, protecting sensitive products from degradation.

- Chemical Industry: Nitrogen is employed as a blanketing gas to prevent oxidation and as a purging gas in chemical processes.

- Wine Production: Nitrogen is used in winemaking to prevent oxidation and preserve the quality of the wine during bottling.

- To view a full list of applications, please click the following link: Nitrogen Gas Generator Applications.

Choosing the Right Nitrogen Gas Generator

Selecting the appropriate nitrogen gas generator depends on several factors, including the required purity level, flow rate, and specific application needs. Gas Generation Solutions offers a range of nitrogen gas generators designed to meet the diverse requirements of various industries, ensuring that you find the perfect solution for your nitrogen gas needs.

Conclusion

Nitrogen gas generators represent a smart investment for businesses looking to improve efficiency, reduce costs, and enhance the reliability of their nitrogen gas supply. With the ability to produce nitrogen on-demand, at the required purity and volume, these systems offer a practical solution to meet the growing demand for nitrogen gas across various sectors. Gas Generation Solutions is committed to providing high-quality nitrogen gas generators, tailored to the specific needs of our clients, ensuring optimal performance and sustainability.

For more information on how our nitrogen gas generators can benefit your business, visit our website or contact us today.

For more information, please fill out our contact form by clicking here.

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR