Oxygen Gas Generators PSA

PSA Oxygen Gas Generators: Cost-Effective Solution for Your Industrial Oxygen Needs

PSA Oxygen Gas Generators: Cost-Effective Solution for Your Industrial Oxygen Needs

If your business requires a reliable and cost-effective source of oxygen, a PSA (Pressure Swing Adsorption) oxygen gas generator could be the solution you need. PSA oxygen generators are widely used in a variety of industries, including medical, pharmaceutical, petrochemical, and bio-gas, to name just a few.

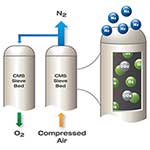

How PSA Oxygen Gas Generators Work

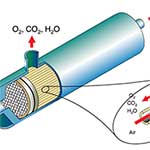

PSA oxygen gas generators use a unique adsorption process to produce high-purity oxygen from compressed air. The process involves passing compressed air through a molecular sieve that selectively adsorbs nitrogen, carbon dioxide, and other trace gases, leaving behind oxygen-rich gas.

The adsorption process occurs at a high pressure, and the adsorbed gases are released when the pressure is reduced. This process is called pressure swing adsorption (PSA), which is where the name comes from.

Once the oxygen has been produced, it is stored in a buffer tank, ready to be used for a variety of industrial applications.

PSA Oxygen Gas Generator

Applications of PSA Oxygen Gas Generators

PSA oxygen gas generators are commonly used in the following industries:

-

- Dairy Farming Digesters: Oxygen generators are used in the dairy farming industry to provide oxygen for the anaerobic digestion of cow manure. Anaerobic digesters use microorganisms to break down organic matter in the absence of oxygen

- Vet Clinics: Oxygen generators are used in veterinary clinics to provide medical-grade oxygen for animals suffering from respiratory distress. The generator produces oxygen on-site, which eliminates the need for the clinic to rely on costly and time-consuming oxygen tank deliveries.

-

- Waste Water Treatment: Oxygen generators are used in the waste water treatment industry to provide oxygen for the biological treatment of sewage. The generators produce oxygen that is dissolved in the wastewater, which promotes the growth of aerobic bacteria that break down organic matter and remove impurities.

-

- Bio Gas: Oxygen generators are used in the biogas industry to promote the growth of anaerobic bacteria that break down organic matter to produce methane gas. The generator produces oxygen that is mixed with the organic matter, creating an ideal environment for the anaerobic bacteria to thrive.

-

- Glass Blowing: Oxygen generators are used in the glass blowing industry to provide a clean and reliable source of oxygen for the torches used in the glass blowing process. The generator produces oxygen on-site, which eliminates the need for costly and cumbersome oxygen tank deliveries, and ensures a consistent flow of oxygen for the glass blower.

-

- Oil and Gas Production: Oxygen is used in the production of oil and gas to increase the combustion efficiency of the fuel and improve overall production efficiency.

-

- Medical: PSA oxygen generators are used in hospitals and clinics to produce oxygen for respiratory therapy and anesthesia.

-

- Pharmaceutical: PSA oxygen generators are used in the production of pharmaceuticals and drugs.

-

- Petrochemical: PSA oxygen generators are used in the refining and processing of petrochemicals.

-

- Food and Beverage: PSA oxygen generators are used in the food and beverage industry for a variety of applications, including wine and beer production and food packaging.

- Bio Gas: Oxygen generators are used in the biogas industry to promote the growth of anaerobic bacteria that break down organic matter to produce methane gas. The generator produces oxygen that is mixed with the organic matter, creating an ideal environment for the anaerobic bacteria to thrive.

Cost Savings and Quick Payback

One of the most significant benefits of PSA oxygen gas generators is their cost-effectiveness. Unlike traditional oxygen delivery methods, such as liquid oxygen tanks or cylinder deliveries, PSA oxygen generators do not require costly transportation or storage fees. Additionally, the cost per cubic meter of oxygen produced by a PSA generator is significantly lower than other delivery methods.

PSA oxygen gas generators also have a quick payback period. With lower operating costs, businesses can recoup their investment in a PSA generator in as little as 1-2 years, depending on the level of usage.

Invest in a PSA Oxygen Gas Generator Today

If your business requires a reliable and cost-effective source of oxygen, a PSA oxygen gas generator is an excellent investment. With their unique adsorption process, PSA generators produce high-purity oxygen on-site, saving you time and money. Plus, with a quick payback period, investing in a PSA generator is a smart choice for any business looking to reduce their operating costs. Contact us today to learn more about our PSA oxygen gas generator solutions.

For more information, please contact our company here.

For more information, please fill out our contact form by clicking here.

CONTACT FORMHOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR