Nitrogen Generator For Cheese Packaging

Nitrogen Gas Generators for Cheese Packaging, Shredded Cheese, Grated Cheese, and Block Cheese are used for flushing the packaging and preserving the quality and freshness of the cheese. This process is called gas flushing and sometimes uses CO2 in addition to nitrogen. The use of CO2 with the nitrogen gas is called MAP (Modified Atmosphere Packaging).

Our company has been providing nitrogen generation systems to some of the largest cheese manufacturing companies for over 20 years. Because of the extreme savings they offer when compared with the steep cost of delivered nitrogen, the generators typically pay themselves back within a 12 to 14-month window.

A nitrogen generator is a perfect alternative for enterprises that have been using liquid nitrogen dewars. Our small nitrogen generators bring you the same speedy payback as liquid bulk tanks—and they’re designed to run for 20 years. It’s a more sustainable, long term solution than liquid nitrogen and built to grow with your company. We service customers with over six nitrogen generators used in various facilities across the country. We can even offer your business lease to own options.

Watch your operations team marvel at the convenience and substantial time and cost savings. Nitrogen Generators for cheese manufacturers gives your business an edge and provide you with the best method for creating a fresh product with the ideal MAP ratio. Your end customer may not know what the MAP process is—but we can guarantee they’ll appreciate it when they finally break into that package of shredded cheese and pour it into that prized enchilada recipe.

Nitrogen Generator and CO2 for MAP packaging shredded cheese?

We can help. We can size the generator to meet any percentage of MAP gas required. We work with all blender manufacturers, and our systems are designed to interface with any blender or mix of gas needed.

How much nitrogen does my cheese packaging machine use?

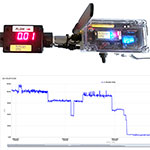

Not sure how much nitrogen you are using? Check out our free flow meter rental option. All of our nitrogen gas flow meters include data loggers and a cellular modem. You can view your flow rate in real-time and download the usage spreadsheet off our dedicated server. Learn more about our line of FlowMe Nitrogen gas flow meters and data loggers here. As always, the FlowMe meters and loggers are free to use.

Nitrogen Generator for Cheese Packaging

Shredded Cheese Packaged Using a Nitrogen Gas Generator

Cheese Blocks Packaged Using a Nitrogen Gas Generator

What purity of nitrogen do you need for cheese packaging?

When it comes to cheese products, be it block, shredded, or sliced, the nitrogen purities range from 99.5-99.9%. Gas Generation Solutions can design any size system to meet your flow and purity requirements.

What are the savings with a nitrogen generator?

Cheese manufacturers opting for delivered nitrogen are draining away their funds. The cost to generate your nitrogen on-site is typically one tenth of the cost for the same results. Nitrogen generators from Gas Generations Solutions yield an average payback time of one year. It’s an easy and obvious way for your business to save tens of thousands of dollars each year.

How to get started generating nitrogen.

If you have not yet started packing your cheese with nitrogen, get in touch with Gas Generation Solutions. We’re standing by and eager to help your company inaugurate its entry into nitrogen gas generation. Because we work with all the major packaging machine manufacturers, we’re familiar with nitrogen measurements for many products and can quickly help you determine your flow rate. Expect as much as a 90% savings in your nitrogen expenses.

Gas Generation Solutions Contact Us Form

Please fill out the form below and we will contact you within 24 hours of receipt. If you need immediate assistance, please call us at 760-505-1300 Thank you.

Gas Generation Solutions gives you the purest nitrogen for food packaging. Call or email today!

FOOD PACKAGING

SNACK FOOD PACKAGING

SALAD PACKAGING

WINE BOTTLING

HOW MUCH N2 DO I USE

FREE FLOW METERS

NITROGEN GENERATORS

SAY NO TO BULK

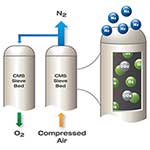

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

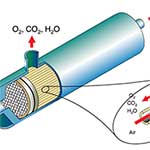

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR

Contact Us Click here to contact our company by email:

Request Quotation If you already know what your current demand is you can click here to fill out our quotation request form. We will have a proposal emailed back to you within 24 hours.