Nitrogen Generators For Vacuum Heat Treating Furnaces

Nitrogen Gas Generators for Vacuum Heat Treating Furnaces is the fastest way to reduce your cost of operation. The savings by switching to a nitrogen gas generator can be in the hundreds of thousands per year.

Vacuum furnaces can use a number of different process gasses. The most common of the gases used is nitrogen. Followed by argon, hydrogen, and helium.

Nitrogen is the most common backfill gas used in vacuum heat treating. It is almost never captured or recycled. This is usually due to the fact that nitrogen is very inexpensive in comparison to other gasses. It is generally nonreactive with a variety of materials. Nitrogen is also used as a partial pressure gas. It has also been proven to reduce heat-up time when used in positive pressure convection heating.

Nitrogen Gas Generation for vacuum heat treatment can be used for any of the following applications. As a quenching gas, as a partial pressure gas, and for backfilling to atmospheric pressure at the end of a cycle. Our systems are designed to produce nitrogen either on-demand or for High-Pressure Quench.

Are you looking for a high-pressure nitrogen generator for high-pressure vacuum quench? We design systems that can meet any volume, pressure, and demand. From 120 PSI to 500 PSI. We also build cylinder filling systems as well at pressures of 2200 PSI to 6,000 PSI.

How about nitrogen and hydrogen mix for high gas pressure quenching? Our systems can be run with a mixer to produce a desired nitrogen / hydrogen gas mix for vacuum heat treating. This method is used to increase the cooling rate. The most common mixture is 97% nitrogen, 3% hydrogen. The results are equivalent to those produced by oil quenching, case hardening, etc.

Nitrogen Generator For Seco Warwick Vacuum Heat Treating Furnace

Nitrogen Generator For IPSEN Vacuum Heat Treating Furnace

What purity of nitrogen do you need for Vacuum Heat Treatment?

When it comes to Vacuum Heat Treating, the nitrogen requirements observed range from 95-99.999%. We can design any size system to meet your flow and purity requirements. Not only do we have extensive knowledge of the heat treating industry we also do our own measurements on your current system to verify your requirements. This is all done at no charge to the client.

What are the savings with a nitrogen generator?

The cost to generate your nitrogen on-site is typically 1/10th the cost of delivered nitrogen. Our nitrogen generators have an average payback of one year. One thing is certain when it comes to Vacuum Heat Treating: those who opt-in to on-site nitrogen generation for vacuum heat treatment will save tens of thousands of dollars to hundreds of thousands each year—this level of savings allows you to grow your business faster, and make more money.

How to get started generating nitrogen.

If you have not yet started using nitrogen gas for vacuum heat treatment, get in touch with Gas Generation Solutions so we introduce you to the world of nitrogen gas generation. We work with all the major heat treatment manufactures. This means we can help determine your flow rate. If you are already using nitrogen gas, we can cut your costs an average of over 80% compared to delivered nitrogen. Call or email us today to discuss how we can help.

Nitrogen Generator For TAV Vacuum Heat Treating Furnace

Nitrogen Generator For SOLAR Vacuum Heat Treating Furnace

For more information, please fill out our contact form by clicking here.

CONTACT FORMHP FLOW METERS

NITROGEN GENERATORS

HEAT TREATING

CONTACT US

ALUMINUM DEGASSING

ALUMINUM EXTRUSIONS

AUTOCLAVES

LASER CUTTING

Contact Us Click here to contact our company by email:

Request Quotation If you already know what your current demand is you can click here to fill out our quotation request form. We will have a proposal emailed back to you within 24 hours.

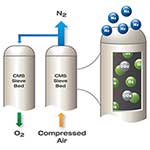

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

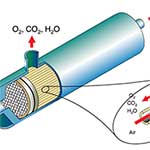

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR