Nitrogen Generators For Snack Food Packaging

Nitrogen gas generators for snack food packaging are used to displace the oxygen in the package prior to it being sealed. Using nitrogen extends the shelf life of the product and preserves the taste, color, and texture of the snack food.

Using a Nitrogen Generator for packaging snack foods is the most cost-effective way to extend your shelf life and preserve freshness.

We have built nitrogen generators for packaging beef jerky, potato chips, popcorn, trail mix, nuts, dried fruit, and chocolate. We also have installed units for gluten-free, vegan, and organic snacks. If you are making a new snack and not sure about using nitrogen please give us a call, we’re here to help.

Our nitrogen generators for snack foods average a payback of one year when compared to delivered nitrogen. With systems operating 20 years, the savings will continue to grow year after year.

Nitrogen generators are size based on your packaging machine’s hourly flow. If your current unit does not have a flow meter we can help. We designed and built a new point of use nitrogen gas flowmeter with a wireless data logger and cellular modem. This unit is designed to go inline between your nitrogen gas supply and the packaging machine. The best part is we send you this unit for free. Give us a call or click the following link to learn more. FlowMe Nitrogen Gas Flow Meter for Packaging Machines.

Nitrogen Generator for Snack Food Packaging

Snack Foods Packaged Using a Nitrogen Gas Generator

Snack Foods Packaged Using a Nitrogen Gas Generator

What purity of nitrogen do you need for snack food packaging?

When it comes to snack foods, be it chips, crackers, or jerky, the nitrogen purities range from 99.5-99.9%. We can design any size system to meet your flow and purity requirements.

What are the savings with a nitrogen generator?

The cost to generate your nitrogen on-site is typically 1/10th the cost of delivered nitrogen. Our nitrogen generators have an average payback of one year. Companies that choose to generate their nitrogen gas on-site will save tens of thousands of dollars each year.

How to get started generating nitrogen.

If you have not yet started packing your snack product with nitrogen, get in touch with Gas Generation Solutions so we can introduce you to the world of nitrogen gas generation. We work with all the major packaging machine manufacturers. This means we can help determine your flow rate. If you are already using nitrogen gas, we can cut your costs an average of over 90% compared to delivered nitrogen. Call or email us today to discuss how we can help.

For more information, please fill out our contact form by clicking here.

CONTACT FORMCOFFEE PACKAGING

CHEESE PACKAGING

SALAD PACKAGING

WINE BOTTLING

HOW MUCH N2 DO I USE

FREE FLOW METERS

NITROGEN GENERATORS

SAY NO TO BULK

Contact Us Click here to contact our company by email:

Request Quotation If you already know what your current demand is you can click here to fill out our quotation request form. We will have a proposal emailed back to you within 24 hours.

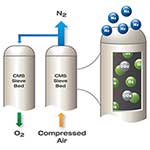

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

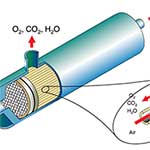

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR