Nitrogen Gas Generator for Aluminum Degassing

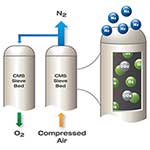

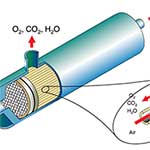

Nitrogen Generators are used in aluminum degassing as a process gas to remove the hydrogen from the molten aluminum. Hydrogen gas is removed by sparging or bubbling the nitrogen gas through the liquid aluminum. The Nitrogen draws the hydrogen gas to it and carries it to the surface where it is released. This is the most popular and preferred method for degassing aluminum.

Aluminum contains a large amount of hydrogen. This hydrogen needs to be removed before casting to avoid defects. Defects to the casting can cause serious mechanical and physical problems to the final product. Since nitrogen is considered an inert gas it is very efficient in reducing oxidation.

The average payback of a nitrogen generator for aluminum degassing is 12 to 14 months. Systems are available in any purity, flow, and pressure configuration required. This makes nitrogen generation one of the most economical ways of aluminum degassing. Lower your cost of operation by generating your nitrogen gas on-site.

Please call or email us to learn more.

Nitrogen Gas Generator for Aluminum Degassing

Gas Generation Solutions Contact Us Form

Please fill out the form below and we will contact you within 24 hours of receipt. If you need immediate assistance, please call us at 760-505-1300 Thank you.

NITROGEN GENERATORS

HEAT TREATING

LASER CUTTING

FREE FLOW METERS

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR

Contact Us Click here to contact our company by email:

Request Quotation If you already know what your current demand is you can click here to fill out our quotation request form. We will have a proposal emailed back to you within 24 hours.