NITROGEN GENERATORS

Gas Generation Solutions has over 20 year’s of experience in the design and engineering of nitrogen generators. We build systems for a variety of industries with the most common goals in mind for our clients. System reliability and cost savings. Our nitrogen generators have an average payback of one year and we have systems operating over 20 years. We are the secrete the gas company does not want you to know about.

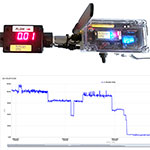

If you need help determining your company’s nitrogen consumption, we can help. We offer full site audit services free of charge. Our line of digital Nitrogen Gas flow meters all have built-in cellular data loggers. We can measure and log your flow rate for a few weeks or months to verify your average consumption and measure any peaks in your usage. This service is also very useful to identify any equipment that may have leaks or is consuming an irregular amount of gas. If you are interested in this service please click here for more information. Free Nitrogen Gas Flow Meter Rental

We specialize in nitrogen generators for the following industries. If you do not see your application listed, please contact us. Whether you are packaging coffee, selective soldering, or laser cutting, we can help reduce your cost of nitrogen gas.

FAQ’s at the bottom of the page.

For more information, please fill out our contact form by clicking here.

Nitrogen Gas Generator

NITROGEN GAS GENERATOR APPLICATIONS

FOOD PACKAGING

COFFEE PACKAGING

WINE BOTTLING

CHEESE PACKAGING

SNACK FOOD PACKAGING

CHIPS AND SNACKS

POPCORN

CANNABIS PACKAGING

SALAD PACKAGING

SALAD CONDIMENTS

LABS AND MEDICAL

PHARMACEUTICALS

ELECTRONICS

WAVE SOLDERING

REFLOW SOLDERING

SELECTIVE SOLDER

LASER CUTTING

HEAT TREATING

VACUUM FURNACE

AUTOCLAVES

ALUMINUM DEGASSING

ALUMINUM EXTRUSIONS

SEMICONDUCTOR

METAL 3D PRINTING

PLASTIC INJECTION

FREE FLOW METERS

SAY NO TO BULK

CONTACT US

Frequently asked questions:

How does a nitrogen generator work?

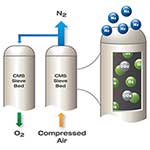

Our systems use clean compressed air to produce pure nitrogen gas. Compressed air is feed into one of two nitrogen sieve beds. These sieve beds are filled with a carbon molecular material that aids in the separation of oxygen molecules from nitrogen molecules. When the first sieve bed is saturated the nitrogen is released into a nitrogen buffer tank. While the saturate bed is being purged the second sieve bed is running through the same purification process to delivery pure nitrogen at a constant rate demanded by your facility.

Does a nitrogen generator use a lot of power?

Yes and no. Typically a nitrogen generator draws about as much power as a light bulb. The main cost associated with generating nitrogen is in the air compressor horsepower and local power price. These are the driving factors that will determine the cost per cubic foot of nitrogen generated by the generator.

What is the cost per cubic foot of nitrogen from a nitrogen generator?

Having run thousands of cost analysis we see an aver cost of $0.05 to $0.12 per hundred cubic feet of gas generated. This is depending on local power and purity required by the plant. If you are comparing your current gas bill it is usually listed in CCF (Hundred Cubic Feet) Or (FTS) which is basically the same as CCF.

What is the average payback on a nitrogen generator?

Our company has an average return on investment of 12 months. In the event we need to do a turn key system the payback is usually only extended to 14-16 months. A turnkey system consists of all the tanks and feed air compressor required to feed the nitrogen generator.

How much does a nitrogen generator cost?

We sell systems starting as low as $5,400 and can up and over $250,000. The demand of the plant and purity required from the system will dictate the size and cost. Regardless of the system size the average payback remains the same.

What kind of maintenance is required on a nitrogen generator?

All of our systems have three inlet air filters that protect the system if the inlet air becomes dirty. The first filter removes water and dirt particles. This filter element is changed once every three months. The second filter removes oil particles and is changed once every six months. The third filter is a charcoal final filter. This is changed once per year. The yearly cost for filters runs a few hundred dollars depending on the size of the system. It is also recommended that you inspect you valves and any safety valves on your system semiannually. You also have the option of calibrating your oxygen analyzer yearly if you desire. We offer this service in addition to selling a small calibration kit so that the client can do the calibration themselves. You will find that the simplicity of the system and the ease of service does not require a maintenance contract.

What size nitrogen generator do I need?

Our company offers free flow meter rental to all potential clients. We have flow meters in every size pipe imaginable. All of them come with cellular modems and data loggers. You will be able to view your flow rate in real time in addition to downloading your data. If you are interested in learning more about our nitrogen gas flow meters with data loggers, please click here. If you know the flow rate of your equipment you can simply email us the flow, pressure required, and application. We can usually reply with a complete quotation the same day.

Contact Us Click here to contact our company by email:

Request Quotation If you already know what your current demand is you can click here to fill out our quotation request form. We will have a proposal emailed back to you within 24 hours.

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

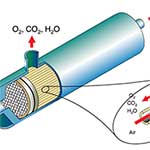

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR