Nitrogen Gas Flow Rates, Requirements, and Usage for Metal 3D Printers.

This page is a reference for Metal 3D Printers that use nitrogen. We have compiled a list of popular printers and if they use nitrogen. The table below will show the Metal 3D Printer Nitrogen flow rate, required pressure, and purity for each model. If you are looking for a Nitrogen Generator for Metal 3D Printers please click here to jump to that page.

You can also contact us directly here. Sales@gasgenerationsolutions.com

METAL 3D PRINTER NITROGEN FLOW RATES, PRESSURE, AND PURITY.

| Metal 3D Printer Model | Type of Printer | Does it use Nitrogen | Nitrogen Flow Rate | Nitrogen Pressure | Nitrogen Purity | Savings Per Year |

|---|---|---|---|---|---|---|

| 3D SYSTEMS | ||||||

| 3D Systems DMP Factory 350 | Laser powder bed fusion (LPBF) | TBD | TBD | |||

| 3D Systems DMP Factory 500 | Laser powder bed fusion (LPBF) | ARGON | TBD | 6-10 bar | ||

| 3D Systems DMP Flex 100 | Laser powder bed fusion (LPBF) | YES | TBD | 6-8 bar | ||

| 3D Systems DMP Flex 200 | Laser powder bed fusion (LPBF) | YES | TBD | 6-8 bar | ||

| 3D Systems DMP Flex 350 | Laser powder bed fusion (LPBF) | TBD | TBD | |||

| 3D Systems ProX DMP 100 | Laser powder bed fusion (LPBF) | YES | TBD | |||

| 3D Systems ProX DMP 200 | Laser powder bed fusion (LPBF) | YES | 5-10 lpm / 30 lpm purge | 5.5 to 7 bar | 99.99% | |

| 3D Systems ProX DMP 300 | Laser powder bed fusion (LPBF) | YES | TBD | |||

| AddUp | ||||||

| AddUp Formup 350 | Laser powder bed fusion (LPBF) | YES | 90 lpm/20min / 2.4 lpm after. | 100 PSI | 99.99% | |

| Concept Laser M2 Series 5 (1000 Watt) | DMLM | YES | 2.5 m3/h Max. 1 m3/h Average | 5 bar | 99.999% | |

| Concept Laser M2 Series 5 (400 Watt) | DMLM | YES | 2.5 m3/h Max. 1 m3/h Average | 5 bar | 99.999% | |

| DESKTOP METAL | ||||||

| Desktop Metal P1 | Fused deposition modeling (FDM) | TBD | TBD | |||

| Desktop Metal P50 | Fused deposition modeling (FDM) | TBD | TBD | |||

| Desktop Metal Production System | Fused deposition modeling (FDM) | YES for Sintering Furnace | TBD | |||

| Desktop Metal Shop System | Fused deposition modeling (FDM) | YES for Sintering Furnace | TBD | |||

| Desktop Metal Studio System 2 | Fused deposition modeling (FDM) | NO | N/A | |||

| DIGITAL METAL | ||||||

| Digital Metal DM P2500 | Binder jetting | NO | N/A | |||

| EOS | ||||||

| EOS M 100 | Laser powder bed fusion (LPBF) | YES | 50 lpm to 2.5 lpm | 4,000 hPa | ||

| EOS M 290 | Laser powder bed fusion (LPBF) | TBD | TBD | |||

| EOS M 300-4 | Laser powder bed fusion (LPBF) | YES | 15 m3/h | 102 PSI | 1000ppm | |

| EOS M 400 | Laser powder bed fusion (LPBF) | YES | 15 m3/h | 102 PSI | 1000ppm | |

| EOS M 400-4 | Laser powder bed fusion (LPBF) | YES | 15 m3/h | 102 PSI | 1000ppm | |

| ExOne | ||||||

| ExOne Innovent+ | Fused deposition modeling (FDM) | TBD | TBD | |||

| ExOne InnoventPro 3L | Fused deposition modeling (FDM) | TBD | TBD | |||

| ExOne Metal Design lab | Fused deposition modeling (FDM) | TBD | TBD | |||

| ExOne X1 160Pro | Fused deposition modeling (FDM) | TBD | TBD | |||

| ExOne X1 25Pro | Fused deposition modeling (FDM) | TBD | TBD | |||

| FARSOON TECHNOLOGIES | ||||||

| Farsoon FS121M | Laser powder bed fusion (LPBF) | YES | 3 lpm | |||

| Farsoon FS273M | Laser powder bed fusion (LPBF) | YES | 3-5 lpm | |||

| Farsoon FS301M | Laser powder bed fusion (LPBF) | YES | 3-5 lpm | |||

| Farsoon FS421M | Laser powder bed fusion (LPBF) | YES | 3 lpm | |||

| Farsoon FS721M | Laser powder bed fusion (LPBF) | YES | 5 lpm to 110 lpm purge | |||

| GE | ||||||

| GE Additive Concept Laser M Line | Laser powder bed fusion (LPBF) | TBD | TBD | |||

| GE Additive Concept Laser X Line 2000R | Laser powder bed fusion (LPBF) | YES | TBD | |||

| GE Additive DMLM M2 Series 5 | Laser powder bed fusion (LPBF) | YES | 2.5 m3/h Max. 1 m3/h Average | 5 Bar | 99.999% | |

| GE Additive EBM | Laser powder bed fusion (LPBF) | NO HELIUM | N/A | |||

| HP | ||||||

| HP Jet Fusion 4200 | TBD | TBD | ||||

| HP Jet Fusion 5200 | TBD | TBD | ||||

| HP Jet Fusion 5210 Pro/5210 | TBD | TBD | ||||

| HP Metal Jet | Binder jetting | TBD | TBD | |||

| MARKFORGED | ||||||

| Markforged Metal X | Fused deposition modeling (FDM) | No | N/A | |||

| ONE CLICK METAL | ||||||

| One Click Metal Bold Series MPrint+ | Laser powder bed fusion (LPBF) | YES | TBD | |||

| RENISHAW | ||||||

| Renishaw RenAM 500Q | Laser powder bed fusion (LPBF) | NO ARGON | N/A | |||

| SHAREBOT | ||||||

| Sharebot Metal One | YES | 2.5 Liters per hour | ||||

| Sharebot SnowWhite2 Nitro | YES | 175 Liters per hour | ||||

| SLM SOLUTIONS | ||||||

| SLM Solutions NXG XII 600 | Laser powder bed fusion (LPBF) | TBD | TBD | |||

| SLM Solutions SLM 125 | Laser powder bed fusion (LPBF) | NO ARGON | 0.6 lpm to 70 lpm purge | |||

| SLM Solutions SLM 280 | Laser powder bed fusion (LPBF) | NO ARGON | 13 lpm to 160 lpm purge | |||

| SLM Solutions SLM 280 2.0 | Laser powder bed fusion (LPBF) | ARGON | 5 lpm to 110 lpm purge | |||

| SLM Solutions SLM 500 | Laser powder bed fusion (LPBF) | ARGON | 16 lpm TO 250 lpm purge | |||

| SLM Solutions SLM 800 | Laser powder bed fusion (LPBF) | ARGON | 5-7 lpm TO 70 lpm purge | |||

| SPEE3D | ||||||

| Spee3D LightSpee3D | NO | N/A | ||||

| Spee3D WarpSpee3D | Cold spray | NO | N/A | |||

| TRUMPF | ||||||

| Trumpf TruPrint 1000 | Laser powder bed fusion (LPBF) | YES | TBD | |||

| Trumpf TruPrint 2000 | Laser powder bed fusion (LPBF) | YES | TBD | |||

| Trumpf TruPrint 3000 | Laser powder bed fusion (LPBF) | YES | TBD | |||

| Trumpf TruPrint 5000 | Laser powder bed fusion (LPBF) | YES | TBD | |||

| VELO3D | ||||||

| Velo3D Sapphire | Laser powder bed fusion (LPBF) | YES | TBD | 99.999% | ||

| Velo3D Sapphire XC Printer | Laser powder bed fusion (LPBF) | YES | TBD | 99.999% | ||

Gas Generation Solutions Contact Us Form

Please fill out the form below and we will contact you within 24 hours of receipt. If you need immediate assistance, please call us at 760-505-1300 Thank you.

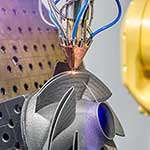

METAL 3D PRINTING

HEAT TREATING

ALUMINUM EXTRUSIONS

FLOW METERS

NITROGEN GENERATORS

ALUMINUM DEGASSING

AEROSPACE

AUTOCLAVES

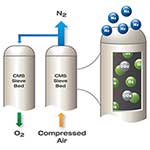

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

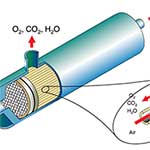

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR

Contact Us Click here to contact our company by email:

Request Quotation If you already know what your current demand is you can click here to fill out our quotation request form. We will have a proposal emailed back to you within 24 hours.