Liquid Nitrogen Generators for On-Site Production

Gas Generation Solutions provides advanced liquid nitrogen generators designed for on-demand nitrogen production, offering cost-effective and efficient alternatives to traditional delivery methods. These systems are ideal for laboratories, industrial operations, fertility clinics, and specialized applications, delivering high-purity liquid nitrogen tailored to your requirements.

With our liquid nitrogen generators, you gain complete control over production, reducing dependency on external suppliers and minimizing operational downtime. Their innovative design ensures consistent quality, easy maintenance, and long-term reliability.

Why Choose Gas Generation Solutions for Liquid Nitrogen Generators?

Gas Generation Solutions provides advanced liquid nitrogen generators designed to meet the needs of industries ranging from laboratories to industrial operations. Here’s why our customers choose us:

•Cost-Effective On-Site Liquid Nitrogen Production: Save money by eliminating delivery costs and relying on an affordable, in-house solution.

•Consistent Supply of Liquid Nitrogen: Avoid interruptions in critical operations with a steady, on-demand supply.

•Compact and Customizable LN2 Generators: From small-scale laboratory units to industrial-grade systems, we have a solution to fit your space and usage requirements.

•Environmentally Friendly Nitrogen Generators: Reduce your carbon footprint by cutting out transportation emissions associated with liquid nitrogen delivery.

•Safe and Reliable: Minimize the hazards of storing large quantities of liquid nitrogen by producing what you need on-site.

•Versatile Applications: Our on-site nitrogen generation systems support applications in laboratories, fertility clinics, food production, and more.

Industrial Liquid Nitrogen Generator for Large-Scale Applications

Small Laboratory Liquid Nitrogen Generator for On-Site Production

Industries and Applications for Liquid Nitrogen Generators

Gas Generation Solutions’ liquid nitrogen systems are the ideal solution for industries requiring reliable and efficient nitrogen production:

1. Laboratories and Research

•Cryopreservation for biological samples and cells.

•Cooling instruments like electron microscopes and mass spectrometers.

•Reliable support for high-precision experiments.

2. Fertility Clinics

•Storage of sperm, eggs, and embryos.

•Safe and consistent supply of liquid nitrogen for fertility procedures.

3. Industrial Operations

•Cryogenic cleaning for equipment maintenance.

•Shrink-fitting and other metal processing techniques.

•Support for advanced additive manufacturing (3D printing).

4. Semiconductor Manufacturing

•Cryogenic cooling for sensitive manufacturing processes.

•Purging systems to maintain ultra-clean environments.

•Reliable liquid nitrogen supply for wafer fabrication and packaging.

5. Food and Beverage

•Flash freezing for preserving food quality.

•Packaging and storage applications in food production.

•Efficient chilling in beverage manufacturing.

6. Healthcare and Medical

•Cryosurgery and other medical treatments.

•Pharmaceutical-grade nitrogen storage solutions.

7. Aerospace and Automotive

•Material testing under cryogenic conditions.

•Advanced manufacturing processes for precision components.

8. Educational and Specialty Uses

•Cryogenic demonstrations in educational settings.

•Artistic and experimental applications in media and performance.

•Agricultural research, such as seed preservation.

Turn-Key Liquid Nitrogen Generator with Closed-Loop Chiller and Air Compressor

Compact Liquid Nitrogen Generator with Integrated Storage Dewar and Components

How Does a Liquid Nitrogen Generator Work?

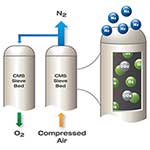

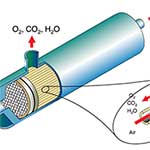

A liquid nitrogen generator produces liquid nitrogen on-site by utilizing advanced cryogenic technology and the Pressure Swing Adsorption (PSA) process. Here’s how it works:

1.Air Compression and Purification: Ambient air is drawn into the air compressor system where it is filtered, dried, and compressed. Impurities such as moisture, oil, and dirt are removed.

2.Nitrogen Separation: Using PSA technology, nitrogen is separated from oxygen and other trace gases. This method relies on specialized carbon adsorbent materials that selectively trap oxygen, allowing pure nitrogen gas to flow through.

3.Pre-Cooling the Nitrogen Gas: The separated nitrogen gas is injected into a pre-cooling system. This step rapidly cools the gas to prepare it for liquefaction.

4.Cryogenic Liquefaction: The pre-cooled nitrogen gas is subjected to intense cooling in a cryogenic system. This process liquefies the nitrogen, achieving a purity of over 99% with oxygen content below 1%.

5.Storage and Dispensing: The liquid nitrogen is stored in a vacuum-insulated tank to maintain its cryogenic temperature. Dispensing options, such as hoses or foot pedals, allow for easy transfer of liquid nitrogen as needed.

6.Intelligent Operation: Many systems feature automated controls, including liquid level sensors and touch-screen interfaces. These controls ensure precise production and storage, optimizing efficiency while minimizing waste.

7.Enhanced Production with BOOST Technology: Certain models include BOOST technology, which increases liquid nitrogen production without requiring additional power or cooling water, making the system highly energy-efficient.

By connecting to a power source, cooling water (or closed loop chiller), and compressed air (or using integrated compressors), liquid nitrogen generators provide a reliable, on-demand solution for industries ranging from laboratories to semiconductor manufacturing.

Frequently Asked Questions (FAQs)

1. What is a liquid nitrogen generator, and how does it work?

A liquid nitrogen generator is a system that produces liquid nitrogen on-site using ambient air as a source. The air is compressed, purified, and cooled to cryogenic temperatures, separating nitrogen from other gases. This process eliminates the need for external deliveries and ensures a consistent, reliable supply of high-purity nitrogen.

2. What are the benefits of using a liquid nitrogen generator over traditional delivery methods?

Liquid nitrogen generators provide numerous advantages, including:

•Cost savings by eliminating transportation and delivery fees.

•On-demand production to match your usage requirements.

•Improved safety by reducing the need to handle and store large quantities of liquid nitrogen.

•Eco-friendly operation with a smaller carbon footprint compared to delivery services.

3. What applications are liquid nitrogen generators ideal for?

Our generators are versatile and suited for various industries, including:

•Laboratories (cryopreservation, cooling systems).

•Fertility clinics (storage of reproductive materials).

•Industrial operations (metal processing, cryogenic cleaning).

•Food and beverage (flash freezing, carbonation).

•Medical (cryosurgery, pharmaceutical storage).

4. How do I choose the right liquid nitrogen generator for my needs?

Selecting the right generator depends on factors such as:

•Daily nitrogen consumption.

•Required nitrogen purity levels.

•Storage and usage conditions.

•Power availability and cooling options.

Our sales engineers can help you evaluate your requirements and recommend the ideal solution.

5. Do I need an external air compressor or cooling system?

Some models come with built-in air compressors and cooling systems, while larger units may require external components. We’ll guide you through selecting the right setup based on your operational needs.

6. How long does it take to install and set up a liquid nitrogen generator?

Installation times vary by model, but most systems can be installed and operational within a few days. Our team provides detailed setup instructions and ongoing support to ensure a seamless transition.

7. What kind of maintenance is required for a liquid nitrogen generator?

Our generators are designed for minimal maintenance. Basic upkeep includes:

•Regular filter replacements.

•Periodic system checks for optimal performance.

•Following the recommended maintenance schedule in the user manual.

8. Can these systems run 24/7?

Yes, all our liquid nitrogen generators are designed for continuous operation, ensuring a steady supply to meet your needs.

9. Is technical support available if I encounter issues?

Absolutely! Gas Generation Solutions offers reliable technical support and resources to address any concerns. You can contact us via phone, email, or our website for assistance.

Take the Next Step with Gas Generation Solutions

Looking for a reliable liquid nitrogen generator tailored to your needs? At Gas Generation Solutions, we help businesses across industries streamline their operations with cost-effective on-site nitrogen production systems.

Contact Us Today

•Learn More: Discover how our high-purity nitrogen generators can support your operations.

•Request a Quote: Let us provide you with a customized solution for your specific requirements.

•Expert Assistance: Speak with our sales engineers to ensure you get the perfect LN2 generator for your needs.

📧 Email: Sales@gasgenerationsolutions.com

📞 Phone: 760-505-1300

🌐 Website: gasgenerationsolutions.com

Or fill out the contact form below, and one of our sales engineers will contact you within 24 hours. Don’t miss the opportunity to optimize your workflow with a cutting-edge liquid nitrogen generation system!

CONTACT US

FREE FLOW METERS

LABORATORIES

NITROGEN GENERATORS

ALUMINUM EXTRUSIONS

AUTOCLAVES

SEMICONDUCTOR

HEAT TREATING

HOW DOES A NITROGEN GENERATOR WORK

NITROGEN GENERATOR COMPRESSED AIR REQ

WHAT IS A MEMBRANE NITROGEN GENERATOR

WHAT IS A PSA NITROGEN GENERATOR